“Friend of Cleantech Commons”, Carbonix, provides a green solution to clean up contaminated environments

Future Cleantech Commons tenant, Carbonix, has been profiled in Northern Ontario Business magazine, which says that the cleantech company is “ready to tackle mining legacy sites” by using wood waste residue to trap industrial contaminants.

Northern Ontario Business writes that Carbonix “has a green solution to clean up contaminated environments”.

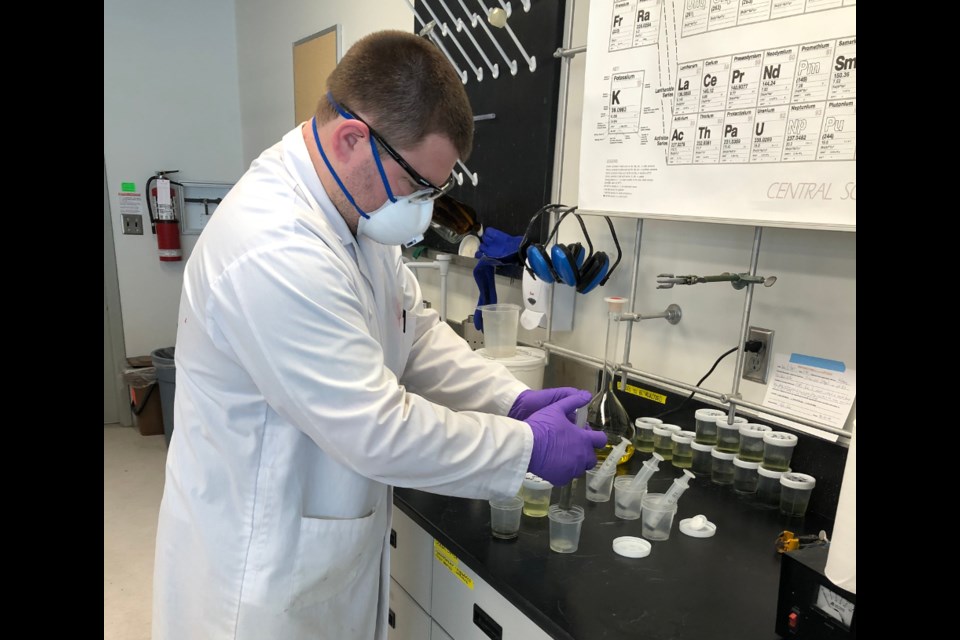

“Carbonix,” the publication writes, “is developing a proprietary process to use activated carbon to treat industrial waste streams and clean up contaminated environments”.

The Carbonix process has been developed in partnership with Trent University’s Dr. Andrew Vreugdenhil, head of Trent’s Inorganic Materials Research Laboratory, which is at the centre of the innovative chemistry advancing methods of transforming various types of carbon waste to produce activated carbon, a highly-absorbent black powder.

Privately-owned Carbonix sees substantial opportunities surrounding abandoned mines in Ontario in supporting remediation efforts to treat tailings and acid rock drainage.

Working with Trent’s Inorganic Materials Research Laboratory, the company has developed a process that can convert large amounts of petroleum coke and boiler char – previously considered waste byproducts – into activated carbon.

“The vision of Carbonix and the expertise and infrastructure here at Trent’s IMRL have generated a process which turns a waste problem into an environmental solution,” Prof. Vreugdenhil told us.

Last July, Carbonix received $3.1 million in federal funding to support their research over a two-year period and scale up the project. Learn more about that here!

Carbonix has also made inroads into Alberta, working with Suncor on a pilot plant to treat water used in the oilsands process, to bring it up to provincial standards, and then release it back into the environment.